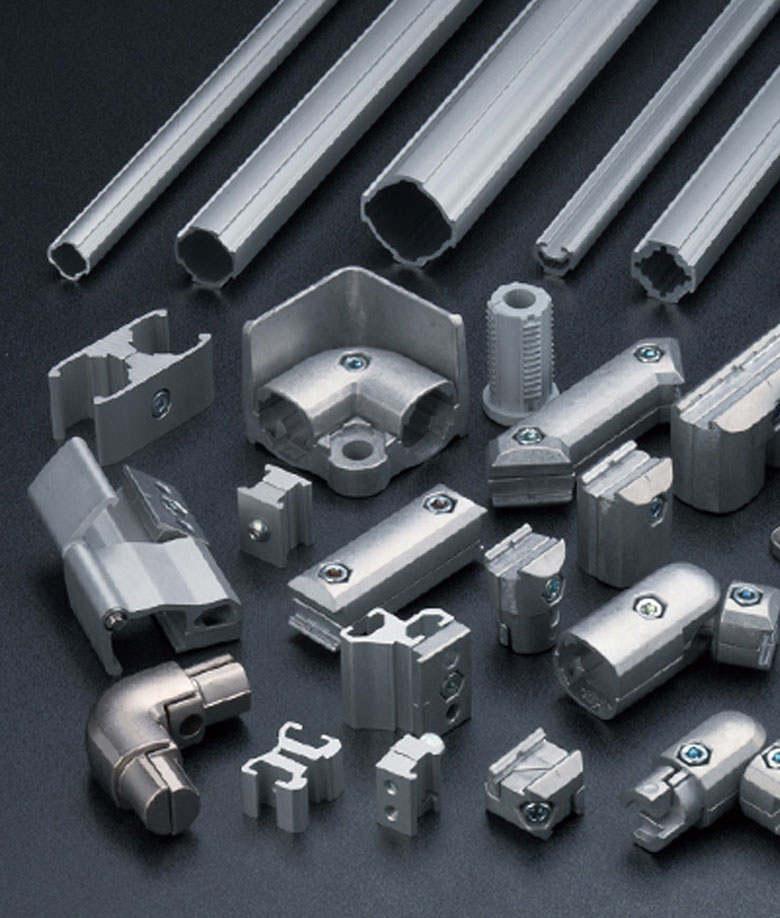

Aluminum profile and connectors

High strength and versatility reduce assembly time

The Green Frame line of recyclable aluminum, manufactured by SUS Corporation, features profiles and connectors that, in addition to being highly resistant, proven by factory tests, are easy and quick to assemble and disassemble.

The range's profiles and connectors, which are 100% aluminum, are also 60% lighter and reduce assembly time by 40% compared to steel structures. Weather resistant, the material is also long-lasting and fully recyclable.

Another highlight of the product is its versatility: the wide variety of fixed and articulated connectors allows the aluminum profile to be easily adapted to different purposes.

Main Applications

- Automobile industry: aluminum profiles can be used in auto parts factory, standardizing the assembly line and adapting to production demands. The manufacturing flow is defined in a straight line, from setup, assembly and inspection to shipment.

- Food industry: aluminum profiles bring functionality and practicality to food packaging due to their reduced weight compared to other materials.

- Pharmaceutical industry: aluminum profiles offer practicality, resistance and protection for pharmaceutical product packaging, ruling out any possibility of contamination.

- Logistics: aluminum profiles allow the creation of dynamic line edges, which integrate ergonomic work benches and automatic load transport, minimizing movements, avoiding accumulations in the packaging process and reducing work time.

- Agriculture: the aluminum profiles are weather resistant, therefore, they can be used in the structure of greenhouses; shelves; harvesters; transport carts; industrial gardens, among others.

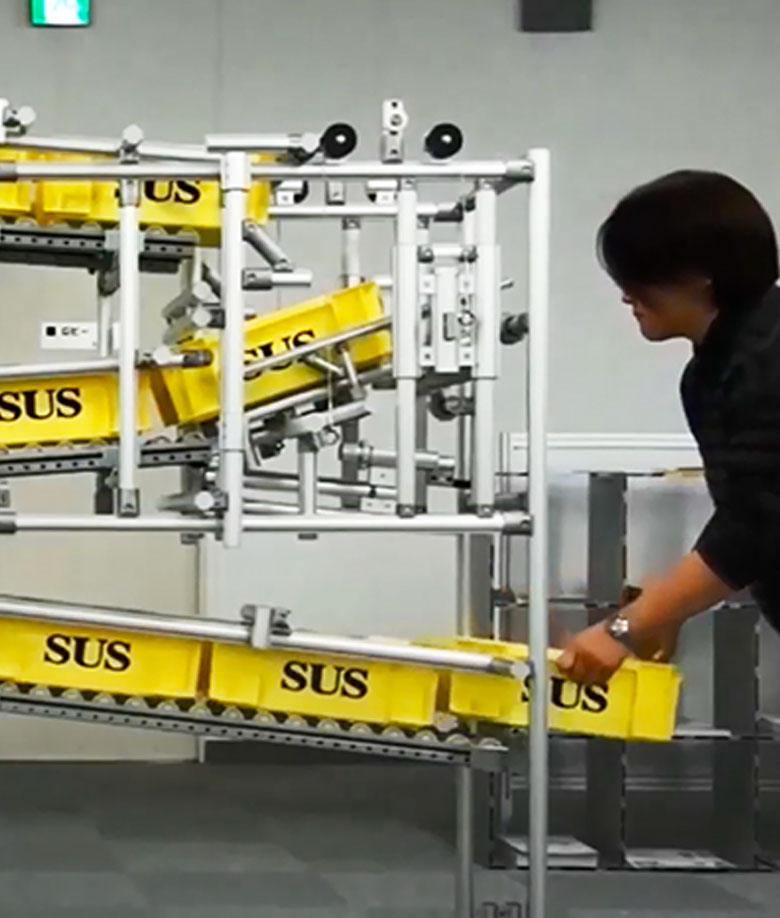

Karakuri Automation

Efficient gravity automation

and without the use of electricity

The engine applies concepts of mechanics and physics. Through the assembly of connectors and aluminum profiles of the Green Frame line, mechanisms are created that allow angular and linear movements, being useful for a wide range of applications.

Karakuri Automation, also known as Gravity Automation, uses the natural weight of items to achieve simple automation, making many tasks that previously required an operator to be automated. And because the system uses no electricity, operating cost savings are even greater while increasing productivity.

The engine applies concepts from mechanics and physics. Through the assembly of connectors and profiles, mechanisms are created that allow angular and linear movements, being useful for a wide range of applications.

Using the physics concepts of pulley and counterweight, it is possible to move items over long distances or change the effort required to move a load.

SUS Corporation

It was founded in 1992 in the city of Shizuoka, Japan and is a manufacturer of aluminum profiles and connections for furniture assembly and gravity automation devices.

Since 2011, CBD has been acting as a representative in Brazil and Argentina for the commercialization, project development and assembly of furniture and karakuris.